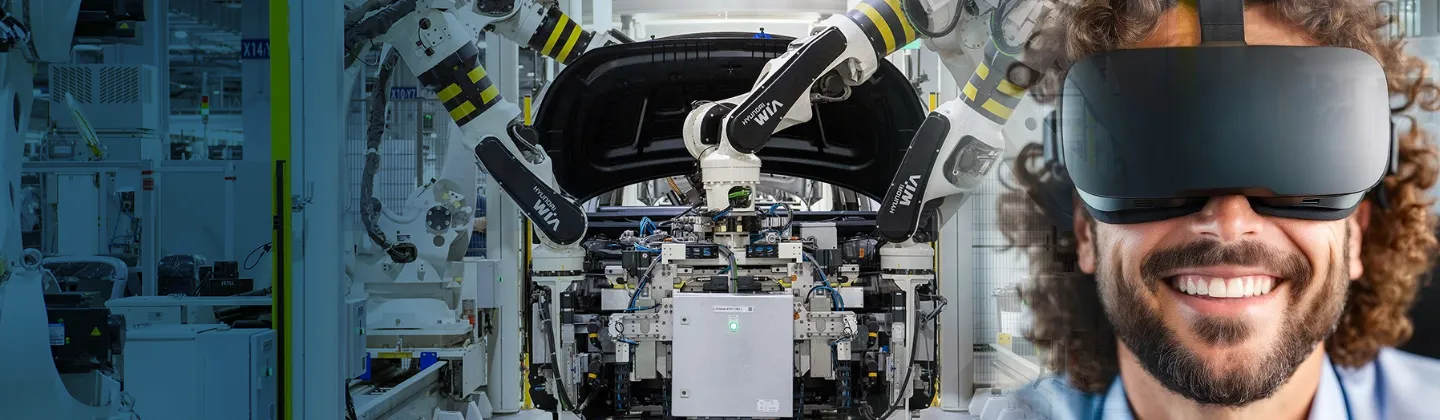

VR and AR transform manufacturing environments by enabling real-time visibility into equipment performance, product models, and shop-floor activities. With IIoT integration, these immersive tools strengthen training, assembly, and maintenance, improving both safety and productivity across the plant floor.

Through VR manufacturing workflows and AR in manufacturing operations, teams gain deeper situational awareness, reducing downtime and improving operational consistency. As more companies invest in AR VR applications in manufacturing, Quantile Tech helps enterprises adopt scalable solutions powered by immersive technology.

VR and AR empower manufacturers to analyze equipment health, understand product behavior, and streamline complex processes. This leads to faster production cycles, superior product quality, and reduced time-to-market. These technologies integrate seamlessly with sensors, cameras, smart wearables, and IIoT devices to deliver intelligent insights..

By leveraging VR manufacturing simulations and AR in manufacturing industry workflows, teams can conduct risk-free training and hands-on learning in front of real machines. Quantile Tech supports enterprises in implementing AR VR applications in manufacturing that improve worker readiness and long-term efficiency across assembly, inspection, and maintenance operations.

Manufacturers can deploy AR/VR capabilities across multiple operational activities on the factory floor, improving efficiency, accuracy, and workforce capability, including :

As VR manufacturing and AR in manufacturing continue to accelerate digital transformation, enterprises rely on robust XR workflows to reduce operational error and enhance decision-making. These features support immersive learning, remote collaboration, and instant access to technical information. Quantile Tech, as a leading VR company and XR company, helps plants adopt scalable immersive solutions that align with real-world production challenges.

Beyond customer presentations, VR plant tours play a strong role in staff onboarding and operational familiarization. Using advanced VR manufacturing environments, Quantile Tech enables companies to conduct safe, repeatable training sessions without disrupting actual production lines, making extended reality a powerful asset for modern plants.

As adoption of VR manufacturing tools grows, companies increasingly prefer simulation-driven training programs that deliver higher retention and measurable performance outcomes. Quantile Tech develops immersive VR and AR in manufacturing industry training modules that help enterprises standardize skill development and improve workforce competency across machinery-heavy processes.

This approach significantly enhances understanding, accuracy, and retention, especially in high-complexity manufacturing environments. With AR in manufacturing applications, Quantile Tech helps factories modernize technical support systems, allowing operators to quickly troubleshoot, assemble, and maintain equipment with minimal training gaps.

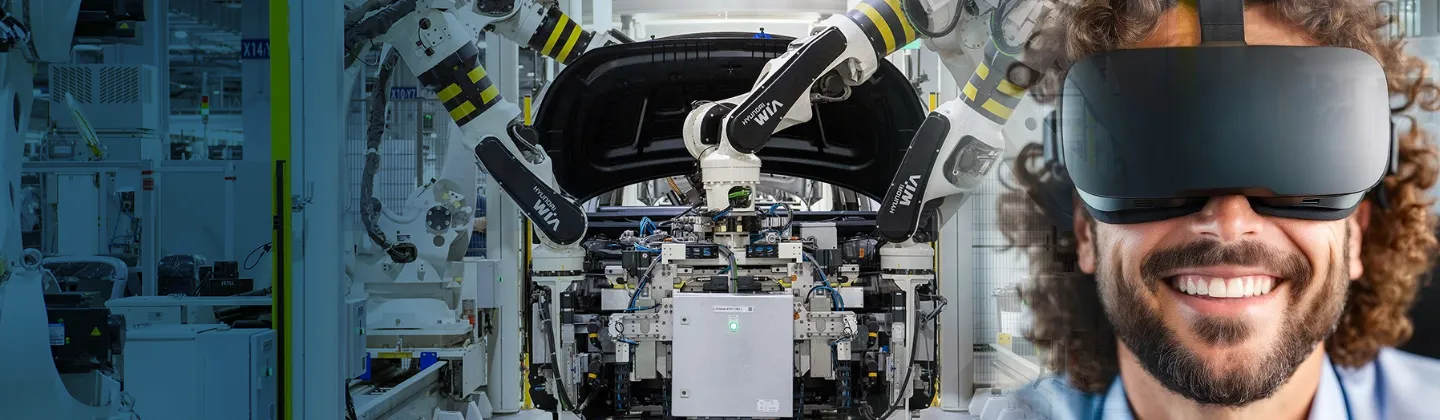

As automotive manufacturing becomes increasingly data-driven, the shift toward VR manufacturing workflows and AR in manufacturing industry practices is accelerating innovation. Quantile Tech supports OEMs and suppliers with XR solutions that enhance collaboration, eliminate rework, and streamline end-to-end automotive operations.

VR and AR solutions help the automotive sector unlock powerful capabilities across design, training, and customer experience. These immersive technologies create highly interactive workflows that improve decision-making and reduce engineering iterations, in the below use case :

By deploying AR VR applications in manufacturing and automotive contexts, companies gain a competitive edge in efficiency and customer satisfaction. Quantile Tech specializes in building XR solutions that enhance automotive showroom experiences, operator training, and technical demonstrations through high-fidelity virtual environments.

With VR manufacturing-grade accuracy and immersive simulation, customers are empowered to make informed buying decisions without the limitations of physical stock. Quantile Tech builds advanced XR solutions that help automotive brands elevate customer engagement and streamline the pre-purchase journey through virtual showrooms.

These simulations are essential not only for customer experience but also for engineering validation and safety training. Quantile Tech integrates VR manufacturing simulation standards into automotive driving modules, enabling lifelike, accurate, and scalable driving experiences for learning and development.

This approach enhances customer engagement and reduces dependency on physical showrooms. Quantile Tech develops AR in manufacturing and automotive applications that bring vehicles to life instantly, offering brands a modern, interactive, and cost-effective way to showcase products.